- Foshan Putie Stainless Steel Co., Ltd.

- > product library > stainless steel sheets 304l

The consumer prices index (CPI) in Britain rose to 2.1 percent year-on-year i...[详情]

| stainless steel sheets 304l |

stainless steel sheets 304l

Properties and uses of stainless steel

As a Low-C 304 steel, in general, its corrosion resistance is similar to that of 304 steel, but its resistance to grain boundary corrosion is excellent after welding or stress. It can also maintain good corrosion resistance without heat treatment. It is generally used below 400 (non-magnetic, operating temperature - 196 ° C to 800 ° C)

It is applied to internal and external open-air machines, building materials, heat-resistant parts and parts with difficulty in heat treatment in chemical, coal and petroleum industries with high requirements for grain boundary corrosion resistance.

The development of 304L stainless steel has made the corrosion resistance, appearance, processability, strength and other characteristics of 304L stainless steel far exceed those of other materials. Moreover, many surface treatment methods of stainless steel can obtain rich and colorful colors and shapes, which makes a great contribution to the development of stainless steel.

304L stainless steel mirror panel

304L stainless steel mirror panel

Surface treatment method and mechanical grinding surface treatment method in the manufacturing process of 304L stainless steel

Summary and application of surface feature manufacturing method

No.1 silver white, matte, a rough, matte surface that is hot rolled to the specified thickness, annealed and descaled, and does not need to have surface gloss

No.2D silvery white is a kind of matte surface processing after cold rolling, heat treatment and pickling, and sometimes the final light rolling is carried out on the roughing roller. 2D products are used for purposes with lax surface requirements, general materials and deep drawing materials

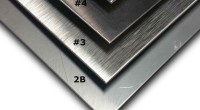

The gloss of no.2b is stronger than that of No.2D. After No.2D treatment, the final light cold rolling is carried out through the polishing roller to obtain appropriate gloss. This is the most commonly used surface processing, which can also be used as the first step of polishing. General timber

BA is as bright as a mirror. There is no standard, but it is usually the surface processing of bright annealing, and the surface reflectance is very high. Building materials, kitchen utensils

No.3 rough grinding: grind No.2D and no.2b materials with 100 ~ 200 # (unit) abrasive belt to grind building materials and kitchen utensils

No.4 intermediate grinding the polished surface obtained by grinding No.2D and no.2b materials with 150 ~ 180# abrasive belt, which is general, and the bright surface with visible 'grains' with specular reflection is the same as above

No.240 fine grinding: grind No.2D and no.2b materials with 240# abrasive belt to grind kitchen utensils

NO.320 ultra fine grinding: grind No.2D and no.2b materials with 320# abrasive belt, the same as above

The luster of No.400 is close to that of Ba. No.2b material is grinded with 400# polishing wheel for general materials, building materials and kitchen utensils

HL hair line grinding: grinding materials with appropriate particle size are used for hair line grinding (150 ~ 240#). There are many grinding particles for buildings and building materials

No.7 close to mirror grinding, use 600# rotary polishing wheel for grinding, for art and decoration

No.8 mirror grinding mirror polishing wheel is used to grind the reflector for decoration

301 stainless steel shows obvious work hardening phenomenon during deformation, which is used in various occasions requiring high strength.

302 stainless steel is essentially a variant of 304 stainless steel with higher carbon content. It can obtain higher strength by cold rolling.

302B is a stainless steel with high silicon content, which has high resistance to high temperature oxidation.

303 and 303se are free cutting stainless steels containing sulfur and selenium respectively. They are used in occasions where free cutting and high surface finish are mainly required. 303se stainless steel is also used to make parts requiring hot upsetting because it has good hot workability under such conditions.

304L is a variant of 304 stainless steel with low carbon content, which is used for occasions requiring welding. The lower carbon content minimizes the precipitation of carbides in the heat affected zone close to the weld, which may lead to intergranular corrosion (welding corrosion) of stainless steel in some environments.

304n is a kind of stainless steel containing nitrogen. Nitrogen is added to improve the strength of steel.

305 and 384 stainless steels contain high nickel and have low work hardening rate. They are suitable for various occasions with high requirements for cold formability.

308 stainless steel is used to make welding rods.

The nickel and chromium contents of 309, 310, 314 and 330 stainless steels are relatively high in order to improve the oxidation resistance and creep strength of the steel at high temperature. 30s5 and 310S are variants of 309 and 310 stainless steel. The difference is that the carbon content is low in order to minimize the carbide precipitated near the weld. 330 stainless steel has particularly high carburizing resistance and thermal shock resistance

316 and 317 stainless steels contain molybdenum, so their pitting corrosion resistance in marine and chemical industrial environment is much better than 304 stainless steel. Among them, 316 stainless steel is made of variants, including low-carbon stainless steel 316L and nitrogen-containing high-strength stainless steel.

316N and free cutting stainless steel 316F with high sulfur content.

321, 347 and 348 are stainless steels stabilized with titanium, niobium, tantalum and niobium respectively, which are suitable for welding components at high temperature. 348 is a kind of stainless steel suitable for nuclear power industry, which has a certain limit on the amount of tantalum and drill.

Weight (kg) * thickness (m) = calculation value

304L stainless steel plate

304L stainless steel plate (5 pieces)

Relevant information editing

Specifications of Colored Stainless Steel Sheet:1) Thickness: 0.4 - 3.0 mm2) Normal Width:a) 1,000mmb) 1,...